ASTM A500, established by the American Society for Testing and Materials (ASTM), stands as a cornerstone in the realm of structural steel specifications. This standard delineates the requirements for cold-formed welded and seamless carbon steel structural tubing, encompassing a versatile array of shapes, including round, square, and rectangular configurations.

Introduced to ensure the reliability and safety of steel components in construction and infrastructure projects, ASTM A500 plays a pivotal role in shaping the modern urban landscape. ASTM A500 specifies many grades with distinct mechanical and chemical qualities to meet a wide range of structural requirements.

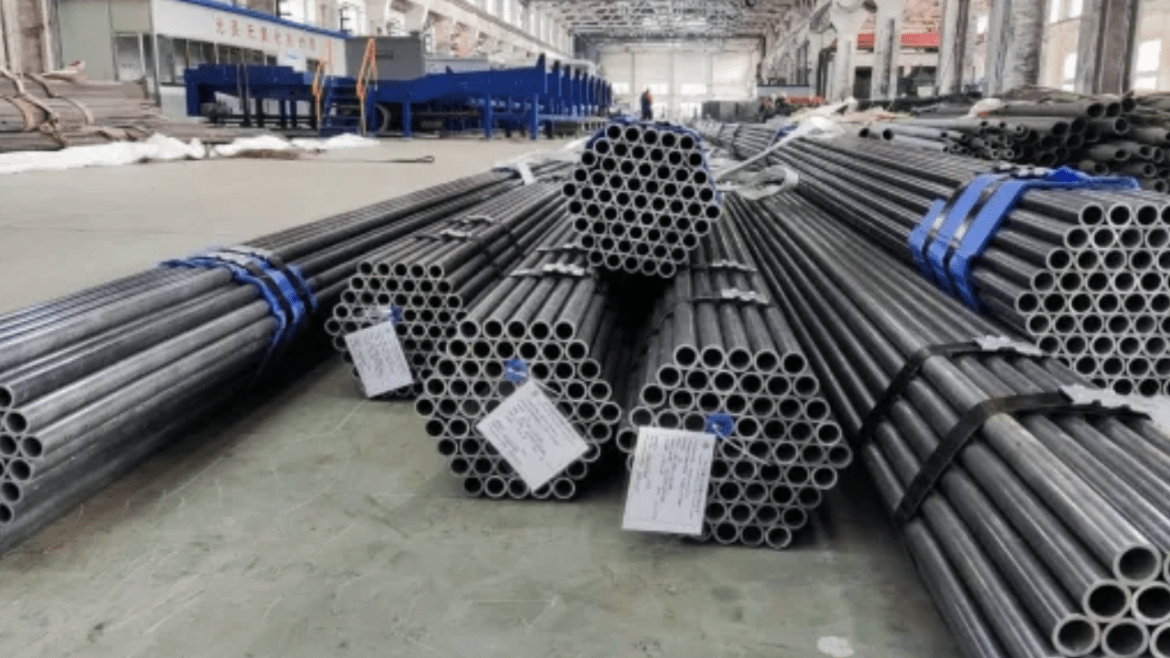

The standard precisely defines dimensional specifications for tubing, including requirements for wall thicknesses and diameters across various geometries. In construction, astm 500 tubes are frequently utilized, particularly in important structural components like supports, beams, and columns. Its versatility in various fabrication methods, combined with severe testing requirements, guarantees that steel tubes meet high quality and performance criteria.

Mechanical Requirements of ASTM A500

The mechanical standards outlined in ASTM A500 are critical for guaranteeing the structural integrity and performance of carbon steel tubing used in a variety of applications, including building and infrastructure projects. In this article, we will look at the mechanical standards given in ASTM A500, explaining their significance and how they contribute to the overall quality of structural tubes.

Yield Strength

One of the basic mechanical requirements established in ASTM A500 is the minimum yield strength of steel tubing. Yield strength refers to the stress at which a material begins to deform plastically. ASTM A500 specifies varying minimum yield strengths based on the shape and grade of the tubing. The parameter is crucial in determining the load-bearing capacity and overall structural performance of the tubing.

Tensile Strength

Tensile strength is another important mechanical parameter described by ASTM A500. It represents the greatest stress that a material can endure when stretched or pulled before necking, which is the point of irreversible deformation. Tensile strength, like yield strength, varies depending on the required shape and grade of tubing. Tensile strength is vital for determining the tubing’s ability to sustain applied forces without failure.

Elongation

Elongation measures a material’s ductility or stretchability before fracture. It is presented as a percentage and indicates the increase in the specimen’s initial length after stretching. ASTM A500 establishes the minimum elongation values for various kinds of tubes. In general, larger elongation values suggest superior ductility. This attribute is critical for determining the material’s response to deformation and strain.

Shapes and Sizes

In addition to mechanical parameters, ASTM A500 specifies the permitted variations in size and mass for various shapes of structural tubes. The standard applies to circular, square, rectangular, and unusual shapes. For example, it specifies the outside diameter, wall thickness, length, and straightness requirements for a round tube. These criteria ensure that the tubing fulfills the dimensions required for good fit and function in a variety of applications.

Permissible Deviations from Straightness

ASTM A500 also specifies the allowed deviations from straightness for structural tubes. The standard specifies how much the tube can depart from straight, ensuring that it is appropriate for construction and fabrication needs. Straightness is vital, especially in applications requiring perfect alignment and fit, such as building frames.

Corner Radii

The standard specifies the permitted corner radiuses for square and rectangular tubing. These radii are critical for preventing stress concentrations at the corners, which can result in cracking or failure under load. By defining acceptable corner radii, ASTM A500 contributes to the structural integrity and durability of tubes in a variety of applications.

Twist

ASTM A500 addresses another mechanical property: twist. The standard establishes limitations on the allowable twist for square and rectangular tubes. The twist is the rotation of one end of a tube relative to the other. Controlling twist is critical for maintaining the structural stability and look of the tubing, especially in applications that need aesthetics and alignment.

Sum Up

Mechanical requirements established by ASTM A500 are crucial to ensuring the quality, durability, and performance of cold-formed welded and seamless carbon steel structural tubing. Compliance with these mechanical criteria is essential for the tube to meet its design specifications. Engineers, architects, and manufacturers rely on ASTM A500 to ensure that carbon steel structural tubes meet safety, reliability, and performance criteria across a wide range of structural applications.